1) There are many reasons why an electrical socket can become faulty.

Most electrical accessories like the plug socket are not designed to last forever as they are relatively inexpensive to purchase in the first place and have moving parts to consider. The humble plug socket can be affected by many issues during its life installed in our homes. We tend to use our electrical sockets day in and day out without a second thought for what is happening inside or behind the socket. We look at the reasons why a FAULTY PLUG SOCKET might occur and how to prevent this from happening.

- Age

- Wear & tear

- Poor quality build

- Accidental damage

- Overheating

- Overloading

2) AGE

The first thing that we look at is the age of the plug socket. There are many electrical plug sockets out there still in operation today that were installed in the 1960s and some of them are still going strong. There could be many reasons why these sockets have not yet apparently failed (some are likely failing but not showing signs) and these reasons are as follows:

2.0.1) They don’t make them like they used to

As manufacturing processes have changed and the necessity for cheap, high-volume products has become the norm in our society. The quality of items has tended to deteriorate, being made from inferior plastics, metals and moving parts. Manufactured to a budget in the cheapest countries possible to maximise profits and appease share-holders.

I am not saying that this has happened to all products in the electrical industry or to all manufacturers but I would certainly have less confidence in modern electrical products to still be working in 2080 as the 1960s products still work now!

2.0.2) The plug sockets have had very little use

The use of an electrical installation will dictate the expected life of the component parts of that installation. An installation that is continually battered by a family of 7 is not going to see many decades of service in comparison to the single occupant that works away most of the time.

2.0.3) Wear and Tear

Every time a switch is operated on a plug socket, a tiny amount of wear and tear takes place. Every time a plug is inserted into a plug socket, the shutter mechanism takes a little wear and tear too. Every time there is electrical current flowing through a plug socket there is wear and tear occurring as the heating and cooling effects of electrical current flowing and ceasing repeatedly are accrued on the plastics, metals, and terminations in the plug socket. Over time this can contribute to a FAULTY PLUG SOCKET along with other factors.

Back to top3) Poor Quality Build

My father always used to say of cars with problems that “It was a Friday afternoon car” or “A Monday car”, the implication being that the job was rushed, the parts slung together and the vehicle suffered from poor quality build as a result.

With modern manufacturing processes this is less likely to happen as most electrical accessories will likely be assembled by machinery to save labour costs HOWEVER, there is still the quality of the materials to consider. If the materials are poor and the construction method is poor then the electrical plug socket is not going to last long.

Earthing bars are a place where manufacturers tend to save a few pence. A thin earth bar with the earth terminal ‘floating’ is indicative of a cheaper build quality to many electricians. A good solid chunky earth bar that is embedded and secured in the plastic construction of the plug socket is far less likely to break, torque off or cause problems with installation or further down the line.

Then there are the terminations themselves, using a cheaper grade of metal can mean that terminations don’t hold the electrical wiring as well as they otherwise could. This can lead to overheating, loose connections, screws shearing off, screw heads rounding off and poor installation practice at the start of the plug sockets life.

Back to top4) Accidental Damage

4.0.1) Shutter Mechanism:

Accidental damage can occur through the normal and daily use of an electrical outlet. One of the most susceptible parts to damage is the shutter mechanism. This mechanism is in place so that the Live and Neutral terminals of the socket are not open and therefore not able to be touched until the earth pin is sufficiently in to the plug socket. As this mechanism is a moving part, it is susceptible to break down and failure and is a fairly common failure point especially where a socket is manufactured to a budget rather than a specification. When the shutter mechanism fails, you are likely to struggle to insert and remove plug tops from the socket outlet and it is possible for earth pins to shear off plugs during the effort involved in the insertion and removal process. This can then leave the earth pin stuck in the socket and the Line and Neutral terminals accessible!

4.0.2) General Impact Damage:

Impact damage can occur to socket faces especially in areas where there is high traffic or movement. Installing plastic sockets in a garage that is regularly used and likely to result in knocks and bangs to the socket is asking for trouble. Once a socket face is damaged or cracked, it should be immediately replaced as it only takes a further small knock to cause live parts to be on display resulting in electric shock risk!

Back to top5) Overheating

Electrical plug sockets are susceptible to overheating during normal use and throughout their lives. This overheating can occur due to various secondary issues such as:

- Loose connections

- Corrosion and High Resistance

- Misuse and overload

- Loose connections

The plague of old wiring systems is, amongst other things, the absolute and complete lack of inspection, testing and maintenance. I swear, the common belief is that “We have never had any problems” then there will continue to never be any problems, there are no hidden problems and everything is as perfect as the day it was installed.

Let me assure you, that is NOT the case.

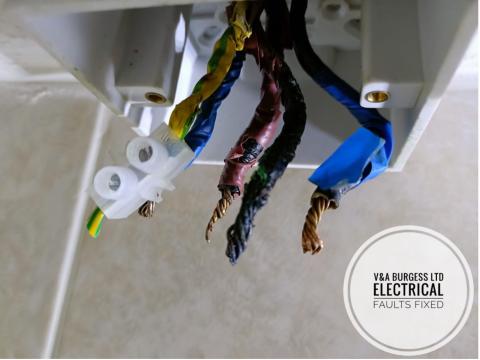

Regular inspection, testing and maintenance (https://www.electricalfaultsfixed.co.uk/electrical-safety-checks-eicr) is a vital part of ensuring the safety of an electrical system. Loose connections are incredibly common and are one of the main causes for electrical fires, melting, burning, appliance and electrical accessory failures, electrical panel, and consumer unit failures and more.

Loose connections present a huge obstacle to electrical current. Electrical current has a difficult time passing from the cable to the plug socket terminal if there is not good contact area. When there is good contact area in the case of tight connections pressed together then there is minimal electrical resistance to the current flow. If we imagine a stadium full of people trying to exit through a single door, it will eventually happen but will take forever along with some flared tempers and problems. Electrical current will actually continue to flow across a small contact area (single door analogy) but it is highly likely that the connection, cable, and electrical accessory itself will overheat drastically and even catch fire whilst doing so.

Back to top6) Corrosion and High Resistance

As we know, plug sockets are not only made from plastics but also metals. Metals will eventually oxidize, corrode, and pit over time and with the addition of accelerants like liquids, moisture, dirt, and debris. When metals become corroded like this, their electrical conductivity becomes affected. This means that the surface of the metal no longer provides a nice low resistance path for electricity to flow and there is a struggle for the electrical current to pass from the cable to the plug socket terminals. Copper also becomes oxidized or corroded under the right conditions.

When these issues occur, we can see high resistances develop and this can result in a burnt plug socket (https://www.electricalfaultsfixed.co.uk/blog/burnt-plug-socket) situation occurring. The issues may not reach the stage of a burnt plug socket and may just appear as a FAULTY PLUG SOCKET. Such symptoms could show up as intermittent operation of the socket, overheating socket, cracks appearing on the front of the socket, a crackling plug socket (https://www.electricalfaultsfixed.co.uk/blog/plug-socket-flashes) or other issues.

Back to top7) Overloading

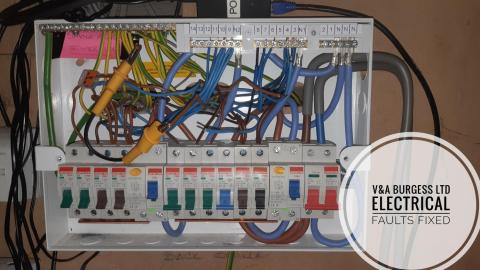

We can often overload our sockets without realising. The typical double socket installed in a bedroom normally has a much easier life than a double socket installed in a kitchen. The living room socket may have to cope with a television and a lamp whereas the kitchen socket may see a high-powered toaster, electric fryer or kettle regularly plugged in and used! The photograph shows what happens when too many high-powered electrical appliances are used in a plug socket.

A FAULTY PLUG SOCKET is a symptom of a wiring system that may not have been checked for a long period of time. We regularly see plug sockets that have burnt out behind or occasionally on the front.

Back to top8) Prevention of problems?

Whilst there are a number of cause of plug socket failure, there are a few ways to prevent this from happening or to pre-empt the problems. Things you can do yourself are:

- Monitor the condition of the electrical accessories and particularly plug sockets

- Don’t overload extension leads or plug socket with high powered appliances

- Consider having your plug sockets replaced if they are very old

- Tackle minor repairs immediately by contacting an electrician to carry them out without delay

- Don’t do DIY electrical works, there are limited safe DIY tasks that can be performed

- Ask an electrician to come and perform a Periodic Electrical Inspection

If your plug sockets are faulty, or you have a burnt socket then stop using it and call a professional to come and check things for you. Don’t live with an electrical system that has these kinds of issues or any kinds of issues, what you may think of as a minor issue or inconvenience could indicate much more serious problems beneath the surface which only a professional could confirm.

Back to top